1

/

of

7

Beer/Gas Tubing by the foot

Beer/Gas Tubing by the foot

Regular price

$1.00 USD

Regular price

Sale price

$1.00 USD

Unit price

/

per

Couldn't load pickup availability

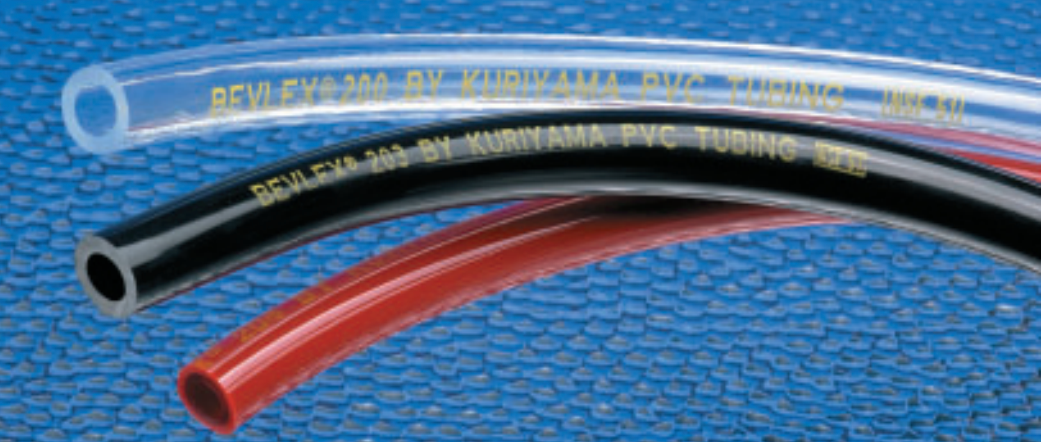

Beer/Liquid:

3/16-inch Inner Diameter (ID):

- Best for most home kegerators.

- Provides the necessary resistance to maintain proper carbonation and a good pour rate.

- Ideal for runs up to 10 feet.

5/16-inch Inner Diameter (ID):

- Use Case: Suitable for longer runs (10–25 feet) in kegerators or small commercial setups.

- Resistance: Provides moderate resistance, making it a good choice for maintaining proper carbonation over a longer distance while still allowing a reasonable flow rate.

- Pressure Needs: Requires slightly higher CO₂ pressure to balance than 3/16-inch lines but less than 1/2-inch.

1/2-inch Inner Diameter (ID):

- Use Case: Typically used in very long runs (25+ feet) or high-flow commercial setups where minimal restriction is needed.

- Resistance: Very low resistance, which can lead to excessive flow rates in shorter runs unless precisely balanced with low CO₂ pressure.

- Pressure Needs: Requires significantly lower pressure to avoid over-carbonation or foaming.

CO2/Gas:

-

5/16-inch Inner Diameter (ID):

- Use Case: The standard size for most CO₂ setups.

-

Advantages:

- Adequate flow for most kegerators, even with moderate line lengths.

- Provides enough volume to maintain consistent pressure.

- Length Recommendation: Works well for runs up to 15 feet or more, as the gas flow doesn’t require as much resistance control as liquid.

-

1/2-inch Inner Diameter (ID):

- Use Case: Suitable for very long CO₂ runs or systems that require high gas volume (e.g., multiple kegs or commercial setups).

-

Advantages:

- Minimal restriction, allowing high flow rates for large setups.

- Considerations: Overkill for standard kegerators and may result in excessive slack if not properly secured.

- Length Recommendation: Typically used in setups with 20+ feet of line or large commercial manifolds.

3/8-inch tubing is ideal for:

- Fast Transfers: High-flow liquid movement for wort, beer, or cleaning solutions.

- Mash/Lauter Tuns: Draining thicker liquids or wort.

- Blow-Off Tubes: Fits larger fermenter openings.

- Pump Systems: Works with most small brewing pumps.

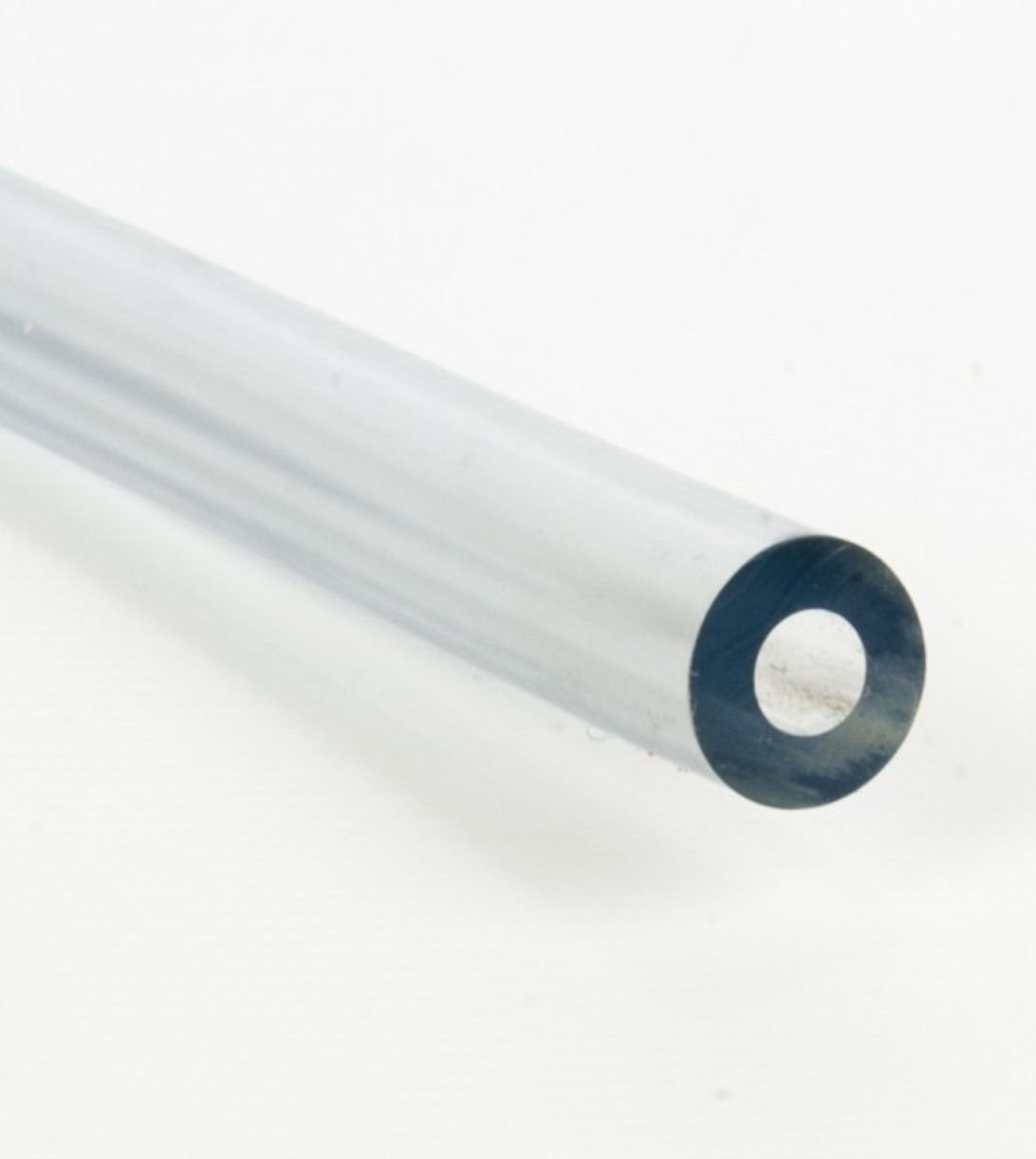

Thin-wall poly tubing:

- Racking/Transferring: Gravity-fed transfers between fermenters, bottling buckets, or kegs.

- Blow-off Tubes: Managing krausen overflow during fermentation.

- Bottling: Connecting a bottling wand to a spigot.

- Cleaning: Directing cleaning solutions in vessels and equipment.

Limitations:

- Not for hot liquids (use silicone tubing).

- Not for pressurized systems (use reinforced tubing).

Share